|

General Purpose Car Repairs |

|

Click image for info |

|

Waterproof Boats |

|

Click image for info |

|

Specialty Chemical Resistant |

|

Click image for info |

|

Epoxy Canoe / Kayak Repair |

|

Click image for info |

See below for further selections.

| SPECIALTY CORROSION RESINS | |||

| PART # | NAME | Description | |

| Derakane 411 | Used for contact molding, pultrusion, matched die molding, continuous laminating, and filament winding (medium viscosity) | ||

| Derakane 411C | Used for resin transfer molding, centrifugal casing, and applications requiring fast wet-out. (lower viscosity version of Derakane 411) | ||

| Derakane 441-400 | Contains less styrene than Derakane 411 resins. Used for contact molding, pultrusion, matched die molding, continuous laminating, and filament winding (medium viscosity) | ||

| Derakane 470 | Offers a high resistance to solvents and chemicals, good retention of strength and toughness at elevated temperatures, and excellent resistance to acidic oxidizing environments. | ||

| Derakane 8084 | Resin of choice as a primer to prepare a substrate surface for application of a corrosion resistant lining. Can be used for RTM, hand layup, spray up, filament winding and other industrial FRP applications. | ||

| Derakane 510A | Designed to offer the maximum degree of fire retardance combined with enhanced chemical resistance and toughness. Fire retardance is achieved without additives, so chemical resistance is maintained and visual inspection of fabricated articles is not impaired. | ||

| Derakane 510N | The preferred resin for strong oxidizers, such as chlorine and chlorine dioxide. Used extensively in FRP ductwork, stacks, and stack liner applications, equipment specified to handle mixtures of air and hot gases or potentially flammable and corrosive liquids, and flooring compounds where heat and/or fire retardance is required. Offers moderate fire retardance. | ||

| Derakane 510C-350 | Designed for ease of fabrication using hand lay-up, spray-up, filament winding, compression molding, resin transfer molding techniques and pultrusion. Offers a high degree of fire retardance while providing excellent chemical resistance and toughness. | ||

| Hetron 942/35 | High performance epoxy vinyl ester resin with improved resistance to hydrocarbon solvents and superior thermal properties. Use with equipment requiring superior thermal properties or less than 35% styrene. | ||

| Hetron 980/35 | High performance epoxy vinyl ester resin, formulated to provide maximum heat and corrosion resistance to strong oxidizing chemicals. Use with equipment requiring maximum corrosion resistance to bleach chemicals. | ||

| Hetron FR998/35 | Flame retardant epoxy vinyl ester resin. Class I (ASTM E84) without antimony additives. Improved resistance to hydrocarbon solvents and oxidizing media. Superior thermal properties. Use for equipment requiring superior corrosion resistance and thermal properties to standard flame retardant epoxy vinyl ester resins. Flame retardant applications where translucency is required. | ||

| Hetron 970/35 | Best solvent resistance of any styrenated epoxy vinyl ester resin.Improved thermal properties. Use for equipment where maximum thermal properties or solvent resistance is required. | ||

| Hetron 922 | Corrosion resistant to both strong acids and bases. Inherent toughness provides fabrication advantages and resistance to both impact and thermal shock damage. Use where strong acids and bases are encountered. Meets FDA regulation Title 21 CFR.177.2420. Available in low and medium viscosity and promoted low viscosity versions. | |

|

| Hetron FR992 | Flame resistant version of HETRON 922. Class I (ASTM E84) with the addition of 3% antimony trioxide. Use for flame resistant equipment requiring the corrosion resistance and toughness of HETRON 922 resin. | ||

| Hetron 980 | Superior corrosion resistance and improved thermal properties. Use where equipment requires superior thermal properties and corrosion resistance. | ||

| Hetron 92 | Flame resistant chlorendic polyester resin providing good corrosion resistance to vapors. Use for equipment handling corrosive fumes. Available in low viscosity and without Antimony trioxide. | ||

| Hetron 197 | Highly corrosion and heat resistant. Low flame spread Class II (ASTM E84) can be achieved with the addition of FR synergist. Use where maximum corrosion and heat resistance to wet chlorine and other oxidizing chemicals is desired. Not for caustic service. | |

|

| Hetron 99P | Isophthalic Polyester resin that provides flame resistance and moderate corrosion resistance, Class I (ASTM E84) with the addition of 3% antimony trioxide. Use for equipment handling corrosive fumes and process equipment enclosures. | ||

| Aropol 7241 | Isophthalic Polyester resin that provides good corrosion resistance at moderate temperatures, including hydrocarbon solvent resistance. Use for General purpose corrosion resistant equipment. FDA versions available | ||

| Aropol 7334 | Isophthalic Polyester resin that provides resilience and moderate heat and corrosion resistance. Use for general purpose corrosion resistant equipment. FDA versions are available. | ||

| Hetron 700 | Bisphenol A Fumarate Polyester resin with the broadest corrosion resistance to both acids and bases. Use where maximum resistance to caustic environments is required. | ||

| Marble Resin | |||

| The above resins are available in 1 gallon, 5 gallon and drum sizes. Resins can be promoted and thixed at customer request. Please call for inquiries. 905-579-1433 | |||

A larger repair kit for those bigger projects.

Click for more features and to see what's included.

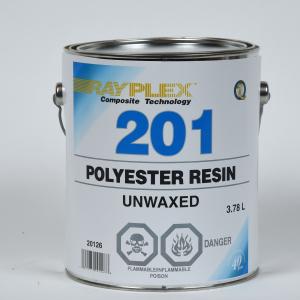

RESIN

Polyester resins are the workhorse of the composite industry. They are available in a wide range of types for different uses. They are often referred to a fiberglass resin or just plain resin. Isophthalic is used for car parts because of its higher heat distortion temperature, use this resin for building water tanks and it also offers a mild corrosion resistance.

Find out more information on the following resins types; Ornathalic (general purpose), Isophthalic, Tooling, Infusion, Casting, Translucent, Vinyl Ester, and Hetron or looking for a resin to repair Fiberglass process equipment.

Check out the resins above for the best match for your project.