Vacuum Bagging

The advantages of vacuum bagging over traditional methods?

- Mechanical pressure compacts the laminate, removing air, humidity, and excess resin, which can all compromise the curing process and the performance of the finished part.

- This compaction improves the fiber-to-resin ratio, which is the key to maximizing the strength-to-weight advantages of any composite.

Some combination of these materials is essential for any successful vacuum bagging system. Before beginning any project, first determine the parameters of your part and your lay-up:

- What is the size and shape of your part?

- Does it have deep cavities or sharp corners?

- What is the temperature range for my lay-up?

Answers to questions like these help you decide best materials for your part. If you're not sure which materials to buy, or if you have questions, give us a call as Rayplex® offers excellent customer service and knowledge of all our products.

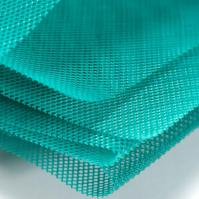

- DESCRIPTION

Econostitch® is a heat set and scoured nylon peel ply with red tracers which make this peel ply more visible before and after a cure, reducing the possibility of the peel ply being left on the part.

Our Econo peel plies are designed to work in resin infusion or hand lay-up processes. Econostitch® assists or eliminates the need for sanding or abrading on your composite laminate.

- BENEFITS

- Peel plies strip off of cured laminates leaving a textured surface, reducing time spent hand finishing.

• Lower cost fabric reduces overall cost of vacuum bag process materials.

• Red pin stripes make fabric more visible to reduce risk of leaving in place after cure.

- TECHNICAL DATA

- 60 in wide Folded

|

Maximum use temperature |

375°F (190°C) |

|

Fiber type |

Nylon |

|

Weight |

2.6 oz/yd² (88 g/m²) |

|

Thickness |

0.006 inch (0.152 mm) |

|

Color |

White |

|

Tracer |

Red |

|

Extractables |

<0.5 % by weight |

|

Shelf life |

Unlimited when stored in original packaging at 72°F (22°C) |

- DESCRIPTION

Econostitch® is a heat set and scoured nylon peel ply with red tracers which make this peel ply more visible before and after a cure, reducing the possibility of the peel ply being left on the part.

Our Econo peel plies are designed to work in resin infusion or hand lay-up processes. Econostitch® assists or eliminates the need for sanding or abrading on your composite laminate.

- BENEFITS

- Peel plies strip off of cured laminates leaving a textured surface, reducing time spent hand finishing.

• Lower cost fabric reduces overall cost of vacuum bag process materials.

• Red pin stripes make fabric more visible to reduce risk of leaving in place after cure.

- TECHNICAL DATA

- 60 in wide Rolled

|

Maximum use temperature |

375°F (190°C) |

|

Fiber type |

Nylon |

|

Weight |

2.6 oz/yd² (88 g/m²) |

|

Thickness |

0.006 inch (0.152 mm) |

|

Color |

White |

|

Tracer |

Red |

|

Extractables |

<0.5 % by weight |

|

Shelf life |

Unlimited when stored in original packaging at 72°F (22°C) |

- DESCRIPTION

Econostitch® is a heat set and scoured nylon peel ply with red tracers which make this peel ply more visible before and after a cure, reducing the possibility of the peel ply being left on the part.

Our Econo peel plies are designed to work in resin infusion or hand lay-up processes. Econostitch® assists or eliminates the need for sanding or abrading on your composite laminate.

- BENEFITS

- Peel plies strip off of cured laminates leaving a textured surface, reducing time spent hand finishing.

• Lower cost fabric reduces overall cost of vacuum bag process materials.

• Red pin stripes make fabric more visible to reduce risk of leaving in place after cure.

- TECHNICAL DATA

- 60 In wide Rolled

|

Maximum use temperature |

375°F (190°C) |

|

Fiber type |

Nylon |

|

Weight |

2.6 oz/yd² (88 g/m²) |

|

Thickness |

0.006 inch (0.152 mm) |

|

Color |

White |

|

Tracer |

Red |

|

Extractables |

<0.5 % by weight |

|

Shelf life |

Unlimited when stored in original packaging at 72°F (22°C) |

OUT OF STOCK

A perforated plastic film may be used in conjunction with the release fabric. This film helps hold the resin in the...

This film resists temperatures up to 350 degrees F. and is puncture resistant and strong. DO NOT count on any...

Description

Wrightlon® 6400 is a nylon bagging film with a good elongation for cure temperatures up to 400°F (204°C).

• Good elongation and strength reduces bridging and resin richness due to low pressure in corners.

• Wide range of available sizes means excess and film waste can be minimized.

• Good temperature resistance provides security during cure temperatures up to 400°F (204°C).

| Test method | ||

| Material type | Nylon | |

| Elongation at break | 375 % | ASTM D 882 |

| Tensile strength | 8000 psi (55 MPa) | ASTM D 882 |

| Maximum use temperature | 400°F (204°C) | |

| Flammability (self extinguishing) | Yes | ATP-5034 |

| Materials to avoid | Phenolic resins/Strong oxidizers | |

| Color | Yellow | |

| Shelf life | Unlimited when stored in original packaging at 72°F (22°C) |

This film resists temperatures up to 350 degrees F. and is puncture resistant and strong. DO not count on any...

Description

Wrightlon® 6400 is a nylon bagging film with a good elongation for cure temperatures up to 400°F (204°C).

• Good elongation and strength reduces bridging and resin richness due to low pressure in corners.

• Wide range of available sizes means excess and film waste can be minimized.

• Good temperature resistance provides security during cure temperatures up to 400°F (204°C).

| Test method | ||

| Material type | Nylon | |

| Elongation at break | 375 % | ASTM D 882 |

| Tensile strength | 8000 psi (55 MPa) | ASTM D 882 |

| Maximum use temperature | 400°F (204°C) | |

| Flammability (self extinguishing) | Yes | ATP-5034 |

| Materials to avoid | Phenolic resins/Strong oxidizers | |

| Color | Yellow | |

| Shelf life | Unlimited when stored in original packaging at 72°F (22°C) |

This film resists temperatures up to 350 degrees F. and is puncture resistant and strong. DO not count on any...

Description

Wrightlon® 6400 is a nylon bagging film with a good elongation for cure temperatures up to 400°F (204°C).

• Good elongation and strength reduces bridging and resin richness due to low pressure in corners.

• Wide range of available sizes means excess and film waste can be minimized.

• Good temperature resistance provides security during cure temperatures up to 400°F (204°C).

| Test method | ||

| Material type | Nylon | |

| Elongation at break | 375 % | ASTM D 882 |

| Tensile strength | 8000 psi (55 MPa) | ASTM D 882 |

| Maximum use temperature | 400°F (204°C) | |

| Flammability (self extinguishing) | Yes | ATP-5034 |

| Materials to avoid | Phenolic resins/Strong oxidizers | |

| Color | Yellow | |

| Shelf life | Unlimited when stored in original packaging at 72°F (22°C) |

Breather cloths allow for vacuum pressure to be applied evenly across the entire surface of a laminate.

Breather cloths allow for vacuum pressure to be applied evenly across the entire surface of a laminate.

Breather cloths allow for vacuum pressure to be applied evenly across the entire surface of a laminate.

Breather cloths allow for vacuum pressure to be applied evenly across the entire surface of a laminate.